07/01/2021

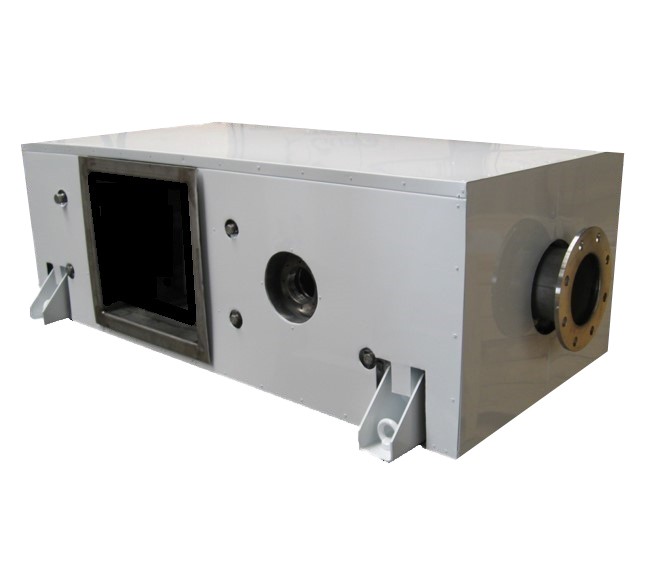

The Emigreen® DPF, diesel particulate filter, combines a powerful performance with easy maintenance and safe working.

A properly maintained Emigreen® DPF guarantees continuous engine operation with no visible exhaust fumes trailing from the vessel or lingering in the water.

Ideally, the essential work of ensuring that all systems on board are properly maintained should not interfere with the sailing schedule.

So the Emigreen® DPF is designed to be maintained by the crew. This eliminates the need to bring an engineer on board to clean the filter at regular intervals.

Emigreen® gives the yacht owner or charterer more control over filter regeneration than any other brand. Also, our systems are designed with the safety of your crew in mind.

Our system anticipates filter saturation before it occurs, and warns the crew in time, so that they can take action to prevent engine problems. The Emigreen® DPF is also unique in its ability to regenerate the filter not only when the engine is running at full capacity, but also at any engine load and even when the vessel is static or moving very slowly.

While it would be beyond our scope to describe the full complexity of our technology, here we explain in detail what differentiates our product from the competition.

Modern monolithic ceramic filters are able to trap even the finest carbon particles. This reduces the soot content of the exhaust to an absolute minimum.

For the system to operate effectively, every so often the soot that builds up in the filter has to be burned off to regenerate the filter. This also ensures that the exhaust back pressure does not exceed the maximum limit for the engine.

A DPF generally functions by forcing exhaust gasses through a filter. Gasses pass through the filter and escape into the atmosphere; while particles produced by incomplete combustion get caught in the honeycomb structure of the filter.

The amount of soot the filter can absorb depends on its volume. As soot accumulates in the filter, it increases back pressure on the engine. This is carefully monitored by the DPF system controller.

When a certain limit value is reached, the system decides that forced regeneration is required and initiates the burn-off process.

The filter is regenerated by burning off the accumulated soot. This happens at temperatures in excess of 400 degrees Celsius.

In some instances, the exhaust gasses produced by the engine are hot enough to incinerate the soot trapped in the filter.

However, if there is not enough thermal energy to guarantee the flow and temperature needed to achieve complete regeneration, we install a burner to generate sufficient heat to convert the soot to ash.

The Emigreen® DPF has four distinguishing features.

The Emigreen® DPF is designed to ensure compliance with the Fuel Standard for Marine Distillate Fuels.

Adherence to the requirements of the ISO 8217:2010 standard results in a cost-effective solution that meets all relevant regulations in international waters.

| Our feature | Your benefit |

| Silicon carbide filter elements | Long operational life |

| Catalytic filters | Reduced exhaust odour |

| Advanced catalyst formulation | Compatible with all marine distillate fuels |

| High storage capacity | Long service intervals |

| Filters easily accessible | Short down time |

| Individually packed filters | Easy to service |

| Heat-resistant stainless steel housing | Long-lasting durability |

Jelle Westerhof is sales manager at Emigreen® and applies our industry-leading solutions to the projects of our clients. Feel free to reach out to Jelle for feedback on this article, for questions and for a free consultation.